Scientific Program

The REGAL scientific program has undergone significant evolution and modernization to consider the challenges related to the achievement of the Sustainable Development Goals (SDGs) of the United Nations 2030 Agenda, which are applicable to the aluminium industry. It is also aligned with the major priorities set out in the Quebec Aluminium Development Strategy (SQDA). The program includes various technological monitoring actions in collaboration with our industrial partners, with the aim of responding to various issues of interest to the aluminium industry as well as to society.

AXIS 01

Production of primary aluminium

Scientific managers: Duygu Kocaefe (UQAC), Seyed Mohammad Taghavi (ULaval)

The production of primary aluminium plays a major role in the Quebec economy, with 7,600 jobs and 8 factories producing 2.9 million tonnes of aluminium annually. However, the process (Hall-Héroult) which it is based upon presents significant environmental challenges: high greenhouse gas emissions (2.3 t CO2eq/t Al), high energy consumption (13-14 MWh/t Al) and production of contaminated waste (60 kt of spent pot linings, 1 Mt of bauxite residue). To meet the objective of reducing environmental impacts, the program for this axis focuses on two themes.

This research theme focuses on improving the quality of carbon anodes in the Hall-Héroult process. Main areas of study include the exploration of alternative sources of coke and biomass, as well as the modelling and optimization of the anode manufacturing process. In-depth evaluation of anode performance in operational conditions and quality control methods are also key aspects of this research theme. The research plan in this theme focuses on:

- Alternative sources of coke and the use of biomass

- Modelling and optimization of the anode manufacturing process

- Performance of anodes in operation

- Development of diagnostic and quality control tools

Co-researchers contributing to this theme:

Houshang Alamdari

Carl Duchesne

Duygu Kocaefe

Yasar Kocaefe

Daniel Marceau

Thierry Ollevier

Seyed Mohammad Taghavi

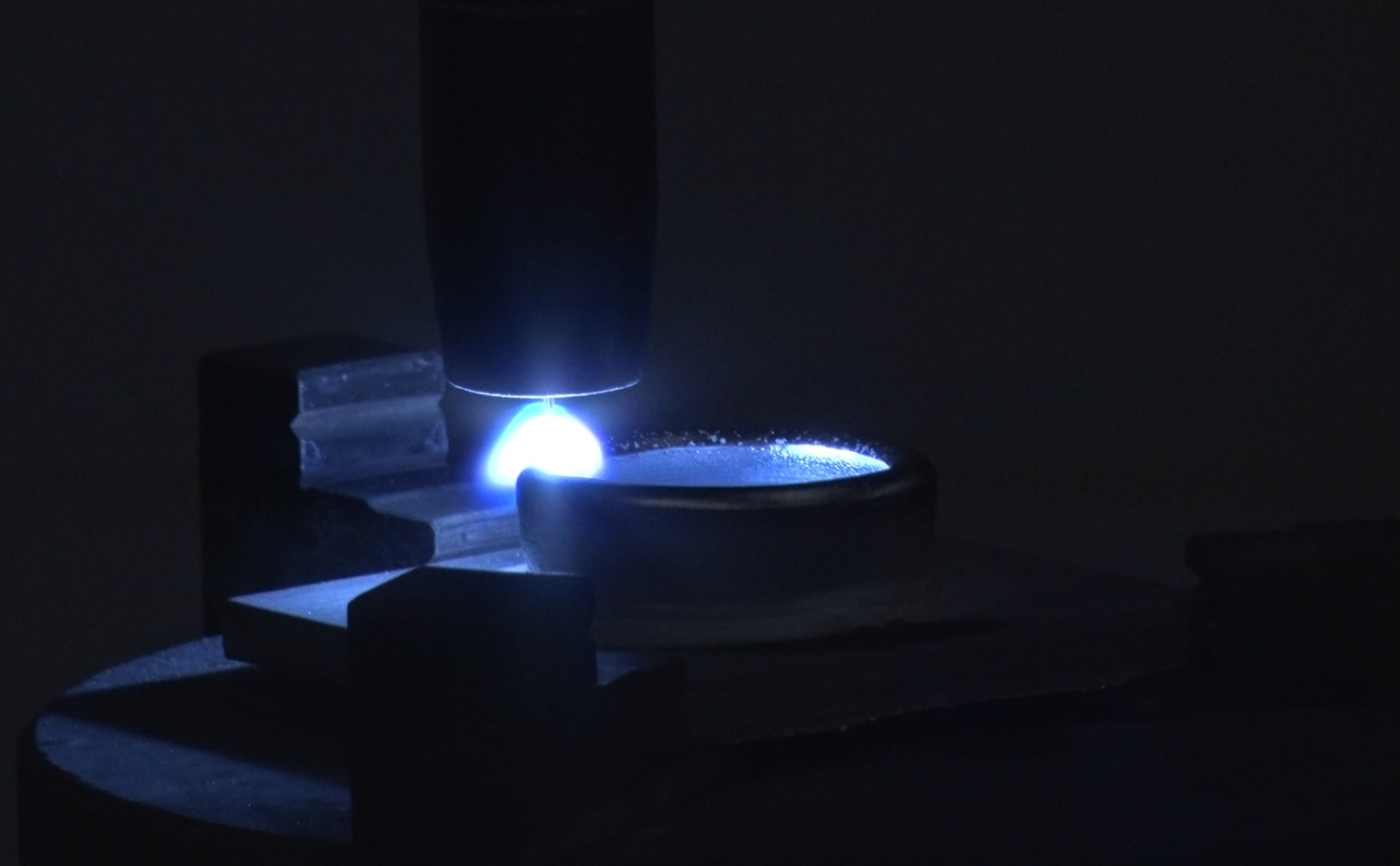

The research in this theme focuses on improving the performance and efficiency of the Hall-Héroult process. By combining experimental studies and numerical simulations, REGAL researchers aim to optimize the design of the electrolysis tank and its components to improve its stability and identify the parameters linked to GHG emissions and the quality of the final product.

The research plan in this theme focuses on:

- Study of the performance of electrode assemblies

- Kinetics and stability of the electrolytic bath

- Identification of factors linked to GHG emissions

- Contamination phenomena of coatings

- Optimization of electrolysis cells

Co-researchers contributing to this theme:

Houshang Alamdari

Patrice Chartrand

Martin Désilets

Lukas Dion

Carl Duchesne

Aimen Gheribi

Laszlo Kiss

Duygu Kocaefe

Yasar Kocaefe

Daniel Marceau

Thierry Ollevier

Gervais Soucy

Seyed-Mohammad Taghavi

AXIS 02

Metallurgy and aluminium transformation processes

Scientific Managers: Julie Lévesque (CTR), Mousa Javidani (UQAC)

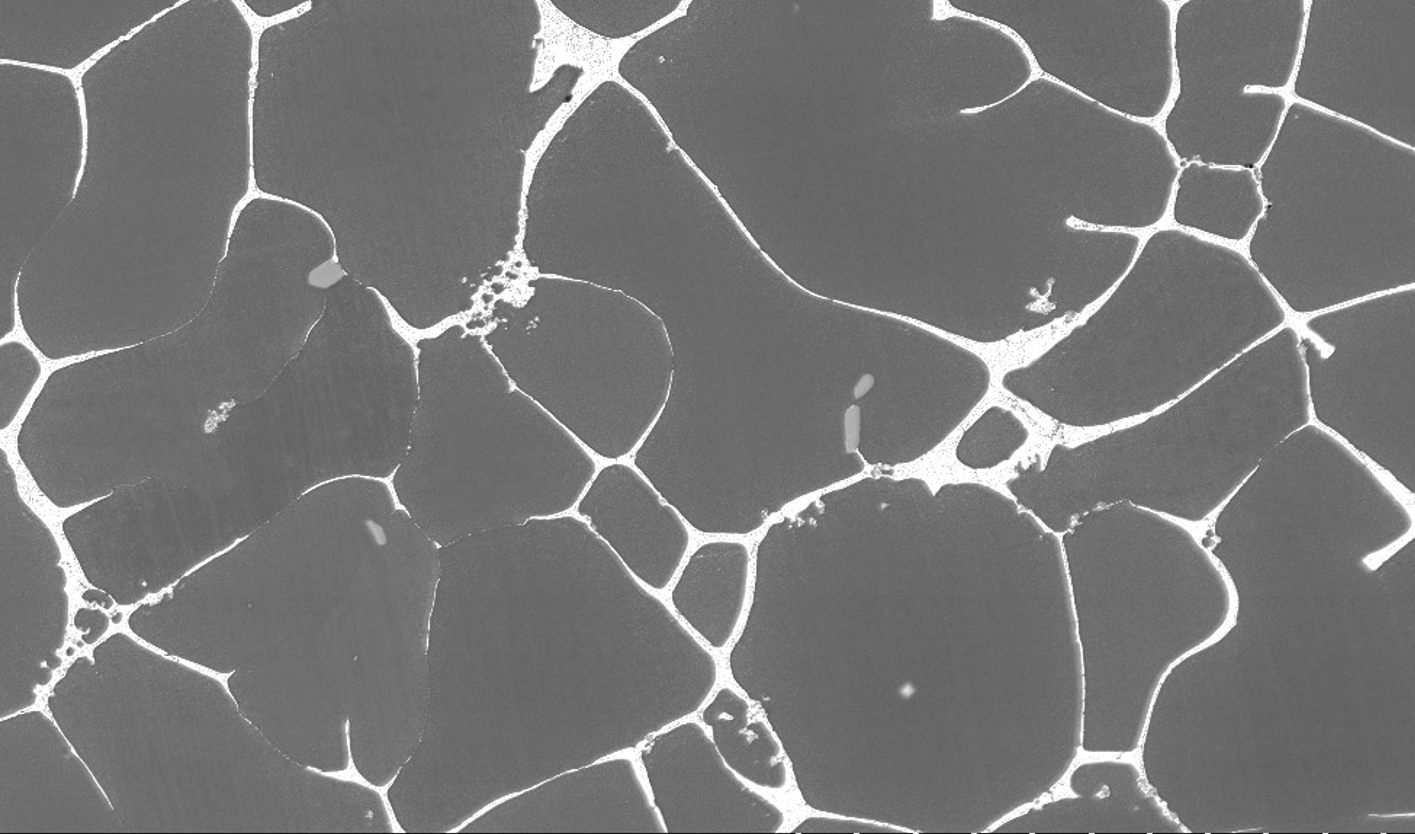

Global demand for aluminium is expected to increase by 40% by 2030. To meet this growing demand, it is essential to study new alloy formulations and improve the speed and efficiency of transformation processes. It should also be noted that Quebec is one of the world’s largest producers of aluminium powder, but the majority is exported due to the low level of activity in the additive manufacturing industry. Priority research in this area is therefore largely based on the discipline of physical metallurgy, which establishes a link between the chemical composition, microstructure and properties of materials, as well as on the study of transformation processes using an approach experimental/digital.

This axis plays a central role between the initial production of aluminium by fusion via the HH process (Axis 1) and the final design of semi-finished and finished aluminium-based products (Axis 3). Therefore, the proposed program is divided into five distinct themes.

By combining these five themes, our program aims to stimulate innovation in the field of aluminium research, while strengthening Quebec’s position as a world leader in this sector.

This theme focuses on the development and improvement of alloys offering significant added value to meet specific market needs. Research topics in this theme include:

- High strength Al alloys for electric vehicles and cables

- 6xxx and 7xxx series ultra high strength Al alloys for automotive vehicles

- New 6xxx series extrusion alloys for structural lightweighting

- New Al alloys with critical and strategic minerals (e.g., Sc, Ti, Mg, Li, Zn)

- Advanced alloys for Al casting

- Impurity tolerant Al alloys

- Alloys to produce Al powder with increased properties

- Casting alloys without heat treatments

Co-researchers contributing to this theme:

Alexandre Bois-Brochu

X-Grant Chen

Franco Chiesa

Vincent Demers

Raynald Gauvin

Jean-Philippe Harvey

Mousa Javidani

Daniel Larouche

David Levasseur

Étienne Martin

Geoffroy Rouget

In this theme, we study innovative methods to improve current processes to effectively increase our production of high-quality aluminium powders. The research plan for this theme focuses on the following subjects:

- Development of alloys with specific compositions for additive manufacturing

- Management of pyrophoricity of Al powders

- Optimization of the particle surface passivation layer

- New implementation processes

Co-researchers contributing to this theme:

Carl Blais

Alexandre Bois-Brochu

X-Grant Chen

Kadiata Ba

Raynald Gauvin

Nicolas Giguère

Geoffroy Rouget

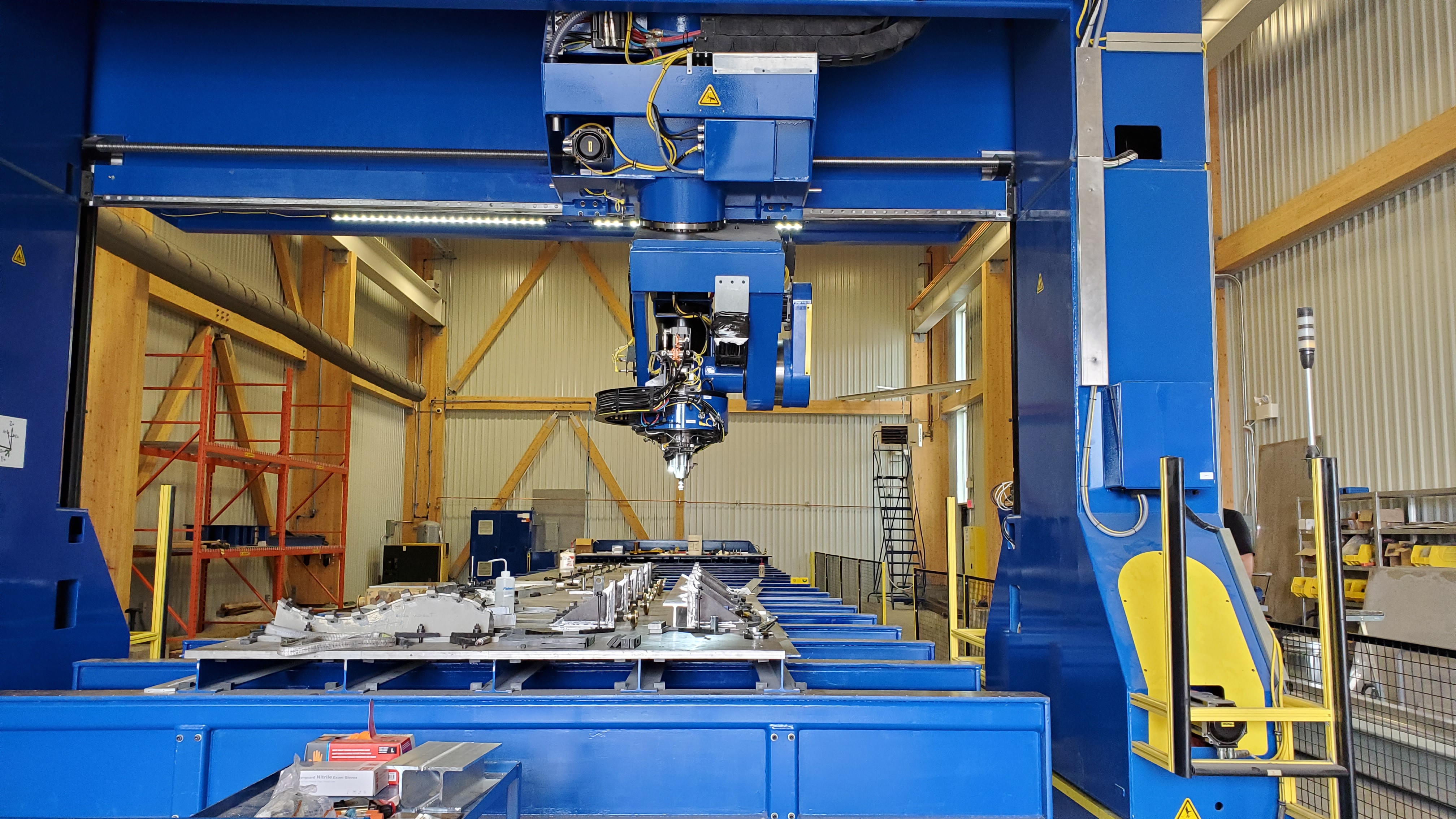

This theme focuses on the optimization of shaping processes, such as forging and extrusion, to obtain aluminium parts with improved mechanical properties. Research topics in this theme include:

- Rolling thin Al sheets for specialty applications

- Thermomechanical and multiscale modelling of the deformation of Al alloys

- Optimization of superplastic forming parameters of 5xxx series

- Microstructure/property correlation during severe plastic deformations

- Improved productivity for parts produced in Al by AM

- Optimization of processing parameters to increase the recyclability of Al alloys

- Casting of thin-walled parts and semi-solid casting

Co-researchers contributing to this theme:

Carl Blais

Alexandre Bois-Brochu

X-Grant Chen

Franco Chiesa

Jean-Philippe Harvey

Mohammad Jahazi

Mousa Javidani

Daniel Larouche

David Levasseur

Étienne Martin

Mamoun Medraj

Geoffroy Rouget

Victor Songmene

In this theme, we explore advanced assembly techniques to create strong, durable structures from aluminium components. Examples of topics covered in this research topic are:

- Al assemblies for electric cars

- Codes and standards for Al assemblies by FSW

- Multi-process Al assembly for the naval industry

- Corrosion-free multimaterial/Al assemblies

- Impact of a saline environment and/or a strong variation in water/air temperature on the assemblies

- Productivity of assembly processes

Co-researchers contributing to this theme:

This last theme of axis 2 focuses on the development of innovative machining techniques to improve productivity and precision when processing aluminium parts. Research topics in this theme include:

- Quality of machined parts and productivity

- Tools and fluids suitable for high performance machining

- Alloy machinability and tool performance

- Simulation and prediction of machining performance

- Automated finishing of machined parts

Co-researchers contributing to this theme:

AXIS 03

Aluminium and its applications

Scientific Managers: Mathieu Brochu (MGU), Liya Li (UdeS)

In Quebec, more than 1,400 companies are active in the field of aluminium processing, generating nearly 30,000 jobs. Combining this with recent investments by the Quebec government in the battery sector, Quebec now has the resources necessary for rapid growth in the use of aluminium. This axis, closely linked to axis 2, highlights the development of new uses and applications with high added value for aluminium in priority areas of activity for Quebec. The proposed program is divided into four distinct themes.

By combining these four themes, our program aims to stimulate innovation in the field of aluminium applications in Quebec while strengthening its position as a world leader in this sector.

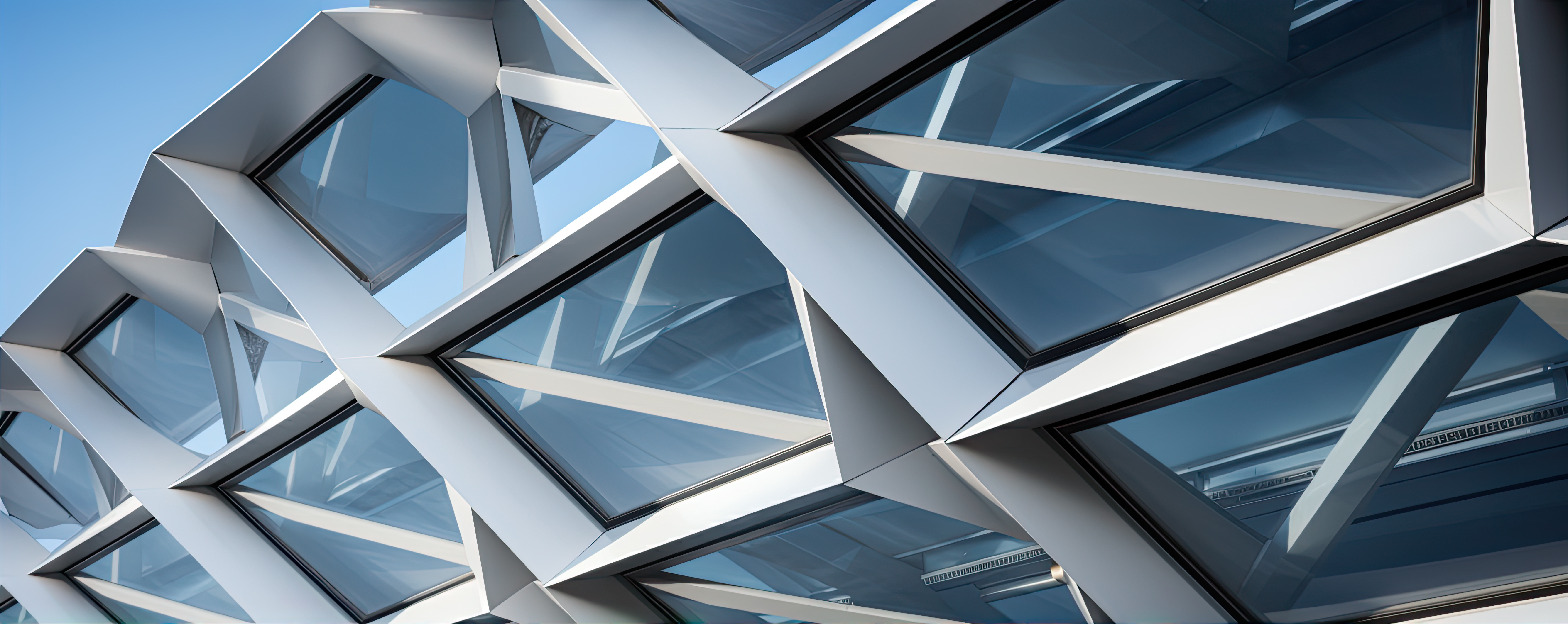

This theme focuses on the increased integration of aluminium in the construction of infrastructure and structures to improve their durability, weather resistance and energy efficiency. The research plans for this theme are focused on:

- Modernization of standards S6 (bridges) and S7 (footbridges): earthquake, fatigue and assembly by FSW

- Quick installation short span 100% Al bridge

- Optimized design rules for extrusions of any section

- Life cycle and total cost of ownership analysis of infrastructure

- Al in telecommunications pylons and towers

Co-researchers contributing to this theme:

Charles-Darwin Annan

Kadiata Ba

Nicolas Boissonnade

Pampa Dey

Charles-Philippe Lamarche

Sébastien Langlois

Liya Li

Marc Oudjene

In this theme, we explore the possibilities offered by the increased use of aluminium in the aeronautical field, whether for the lightweight manufacturing of structures or to improve aerospace performance. The research plans for this theme are focused on:

- Aircraft: Reduction of the BTF ratio (ratio of starting material weight/final part weight)

- Drones and electrification of aircraft: Reducing the weight of structures to maximize energy performance

- Development of new multimaterial manufacturing technologies

- Reliability and safety of structures

Co-researchers contributing to this theme:

This theme highlights the opportunities offered by the increasing use of aluminium materials in land and maritime vehicles, aimed at reducing weight, improving energy efficiency and reducing greenhouse gas emissions. The research plans for this theme is focused on:

- Sizing and manufacturing approaches for reducing the weight of transport structures

- Recreational transport: Development of rigid Al structures to ensure healthy and safe dynamic behaviour

- Collective transport: Corrosion resistance and durability of body elements and chassis

- Maritime transport: Development of Al bridges

- Maritime transport: Fine characterization of the impact of repeated loading on submerged structures

Co-researchers contributing to this theme:

Philippe Bocher

Mohamad Bouazara

Alain Desrochers

Julie Lévesque

Ahmed Maslouhi

Tan Pham

In this last theme of axis-III, we explore promising new applications of aluminium in rapidly expanding areas such as clean technologies, modular construction and other innovative sectors. The research plans for this theme are focused on:

- New surface treatments to improve the bonding capacity of structural adhesives

- Antibacterial coatings

- Anti-corrosion coatings

- Coatings for storage and conversion of renewable energies

- Use of Al for the production and storage of hydrogen

Co-researchers contributing to this theme:

AXIS 04

Aluminium 4.0

Scientific Managers: Martin Otis (UQAC), Tuysuz Oguzhan (POLY)

A suboptimal operation and an unplanned shutdown in the value chain of a process have significant consequences on operating costs. To overcome these findings, the two main pillars of I4.0, cyberphysical systems (digital twin interactions) and artificial intelligence are studied to optimize the Al production and transformation processes in order to maximize their efficiency while ensuring a minimal carbon footprint.

The research carried out within this axis therefore emphasizes a more federated approach concerning the integration of the I4.0 concept in the aluminium sector, by exploiting “big data” to optimize processes, by considering the development of the aluminium smelters of the future or by exploring how to effectively integrate artificial intelligence into these processes.

The proposed program is defined in three distinct themes that guide the research:

This theme focuses on the potential of cyberphysical systems to improve autonomous decision-making in areas such as anode baking, electrolysis cell management and alloy production. The objective is to develop evolutionary or multi-agent algorithms based on data from digital twins in order to optimize these critical processes.

The research plan for this theme is as follows:

- Study of cyberphysical systems, combining the intelligence of electrolysis cell models and anode baking, at the edge and in fog for GHG and energy monitoring

- Design of evolutionary or multi-agent algorithms for a lean flow on anode production, electrolysis cell management and alloy production driven by digital twin data

- Study of the sharing of the degree of decisional autonomy in critical operating parameters for anode baking

- Autonomous adaptation of protocols and compositions of high added value alloys according to physical characteristics and quality

Co-researchers contributing to this theme:

Kevin Bouchard

Julien Maitre

Martin Otis

Éric Poulin

Tuysuz Oguzhan

This theme aims to develop predictive methods for proactive and just-in-time maintenance. Using digital twins, the aim is to estimate the remaining time before failure of equipment such as electrolysis cells and to plan maintenance based on the current state of production. The research plan for this theme is as follows:

- Estimation of the remaining useful life of electrolysis cells and comparative anomaly monitoring with digital twins

- Prediction of just-in-time maintenance windows based on the health of anode baking furnaces and the current state of downstream production

- Automated systems for structural analysis of cells and self-repair during potpourri

Co-researchers contributing to this theme:

Kevin Bouchard

Julien Maitre

Martin Otis

Éric Poulin

Tuysuz, Oguzhan

This theme explores the possibilities offered by multiphysics models and artificial intelligence to optimize the control of electrolysis cells and anode baking furnaces. The objective is to predict key indicators, assist operators with adapted guides, study interactions in teleoperation and assess the impact on the reduction of energy and environmental costs. The research plan for this theme is as follows:

- Prediction with multiphysics models (digital twins) and AI (hybrid) of key indicators related to the optimal operation of electrolysis cells and anode baking furnaces compared with digital twins

- Design of guides to assist operators

- Study of interactions in bilateral teleoperation in an integrated operations centre (IOC)

- Study of the impacts in terms of reducing energy costs, saving raw materials and reducing the environmental footprint

- Automatic adaptation and adjustment of controls according to operator behaviour

Co-researchers contributing to this theme:

Kevin Bouchard

Farbod Khameneifar

Julien Maitre

Martin Otis

Éric Poulin

Tuysuz, Oguzhan

AXIS 05

Responsible Aluminium

Scientific Managers: Patrick Faubert (UQAC), Elmira Moosavi (ÉTS)

Quebec is known for producing the most environmentally friendly aluminium in the world. However, the primary production of this aluminium continues to have negative impacts on the environment. According to the Aluminium Association of Canada (AAC), Quebec will lose its competitive advantage in the production of green (low carbon) aluminium with hydroelectricity in the next 5 to 7 years. Countries such as the United Arab Emirates and China have already started producing green aluminium from renewable energy sources.

In addition, it is essential that this aluminium produced be transformed into finished or semi-finished products that meet consumer needs while respecting the strictest environmental standards. It must also be used, recycled and ideally preserved in an infinite loop through secondary production by fusion.

The research conducted in this area focuses on all aspects of sustainable development, with a particular emphasis on the circular economy and decarbonization. In addition, this axis will also guide the work of axes 1 to 3 to achieve the measurable objectives of the Sustainable Development Goals (SDGs) set by the United Nations.

The program proposed for this axis is structured around three distinct themes.

The theme “Aluminium Recycling” aims to develop a tailored strategy to maximize aluminium recycling. Research in this area focuses on several key aspects, such as the logistics of dismantling multi-material structures, surface decontamination, and recycling/reuse of aluminium powders. The research plan for this theme is as follows:

- Tailored recycling strategy

- Logistics of dismantling multi-material structures

- Surface decontamination

- Recycling/reuse of Al powders

Co-researchers contributing to this theme:

Patrick Faubert

Elmira Moosavi

The theme “Valorization of aluminium production residues” focuses on exploring the different possibilities to give a second life to the residues generated by the aluminium industry. The research conducted in this area aims to find innovative solutions to use these solid residues efficiently and sustainably, while minimizing their environmental impact. The research plan for this theme is as follows:

- Valorization of solid residues from Al production in cement products

- Developments of Nordic geopolymers using solid residues from the Al industry

- Neutralization and valorization of bauxite residues (fertilization in forestry, Nordic agriculture, etc.)

- Capture and reuse of dust, shavings and residues from Al processing

- Recovery and valorization of thermal losses in the Al industry

Co-researchers contributing to this theme:

Patrick Faubert

Mathieu Fiset

Louis Gosselin

Reza Jafari Aminabadi

Elmira Moosavi

The theme “Life Cycle Assessment of Aluminium” focuses on a thorough and comprehensive assessment of the environmental, economic and social impacts associated with the production, use and recycling of aluminium. Research in this area aims to understand the economic dynamics of aluminium recycling, analyze the total cost of use, integrate primary and secondary markets to maximize environmental benefits, and assess the impacts of processes on human health, ecosystem quality, natural resource use and climate change. The research plan for this theme is as follows:

- Economics of Al recycling (dynamics and recycling coefficients)

- Analysis of the cost of ownership

- Integration of primary and secondary Al markets

- Analysis of the impacts of processes on human health, ecosystem quality, resource use and climate change